m880cummins wrote:And, tell me how you went about putting a cummins in a ram charger? Not only did you swap frames but regarding the addition of WEIGHT, how did you resolve this? Surely a ramcharger frame is not rated for that weight.

Okay, time for schooling.

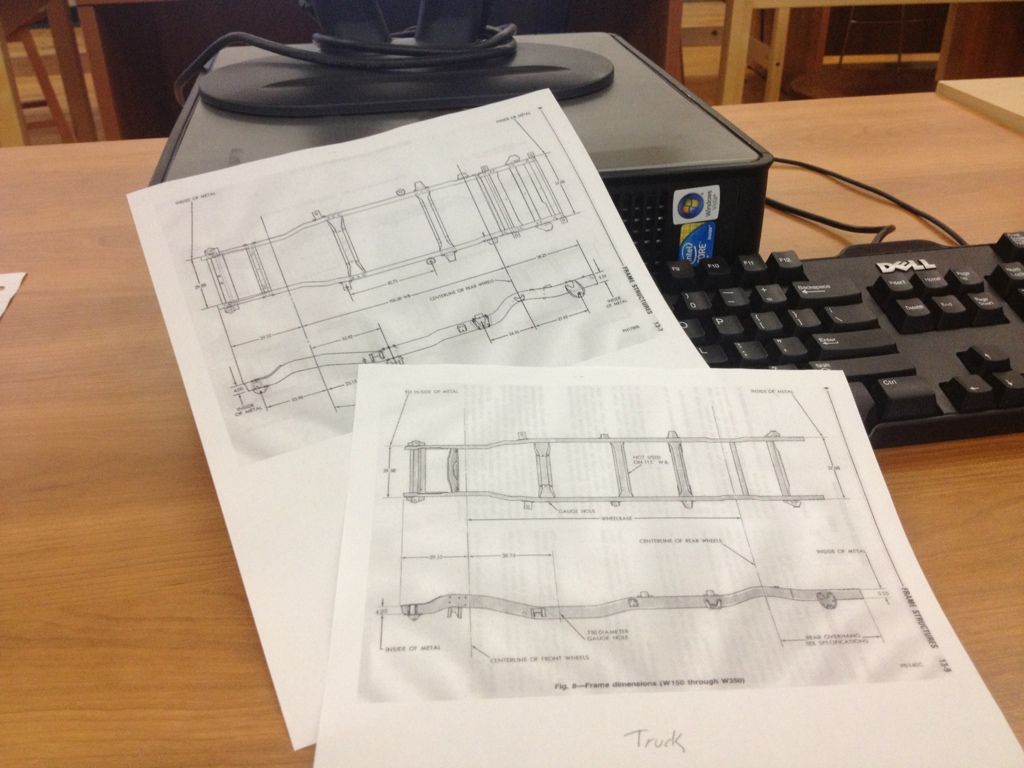

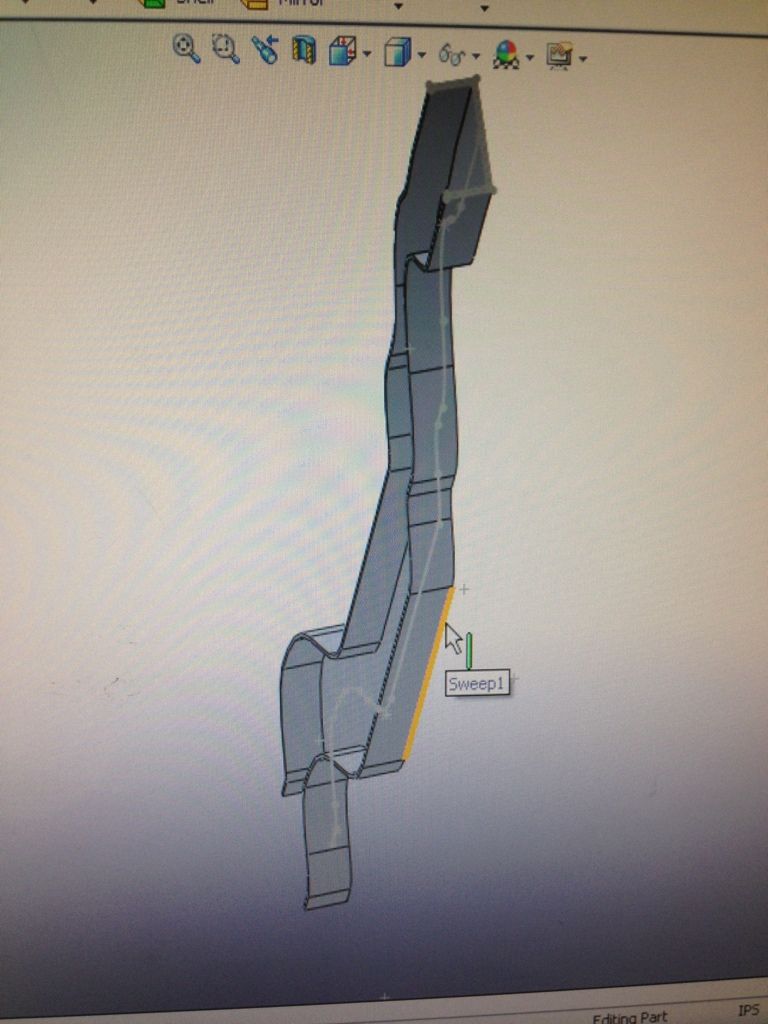

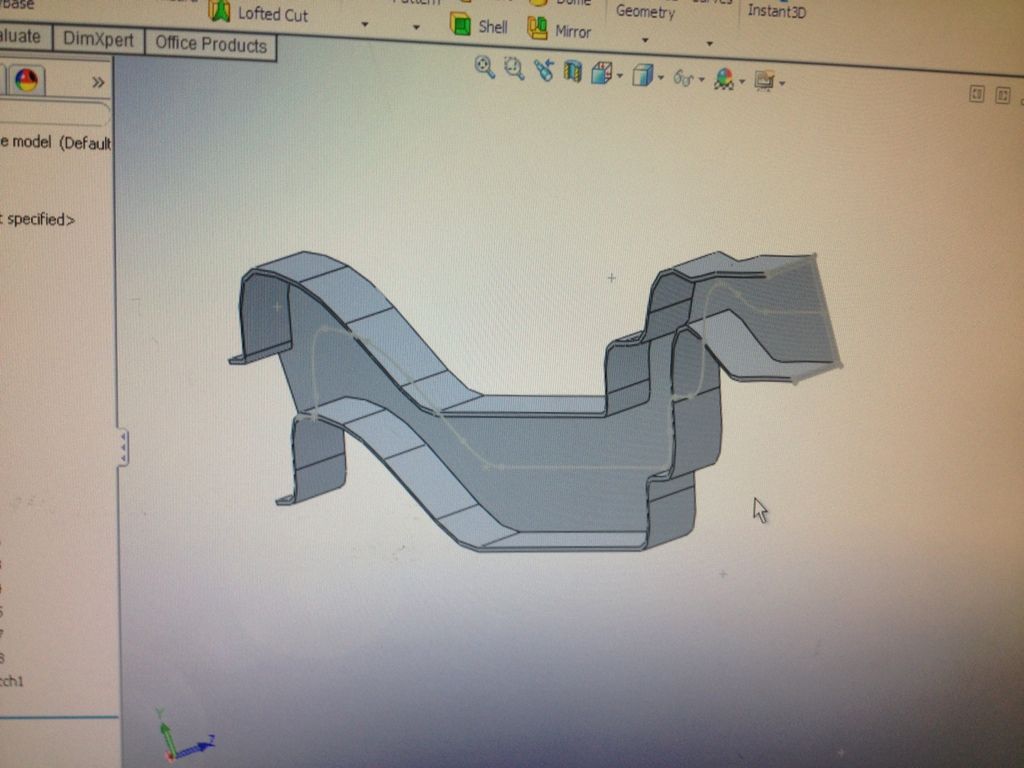

The RamCharger's front frame section is IDENTICAL in crossectional thickness and depth as the front of a 3/4 ton Dodge with a Cummins. the front spring hangars, rear spring hangars, crossmember, even the engine support is the same thickness, depth and height.

I had measured and re-measured all dimensions and parts involved for thickness and the only thing different was the spring rate on the front axle and the front and rear eye bolt diameter, which was increased.

Did you know they use the EXACT same rinky dink front spring mount bracket on a 4X4 Ramcharger as they do on a 4x4 1 ton dually? Probably not, but I did, because I RESEARCHED IT, instead of breaking out the tools and hacking away.

Same goes for the front crossmember support and all other collision-sensitive parts, I researched it all, even down to part numbers, just to be 100% satisfied.

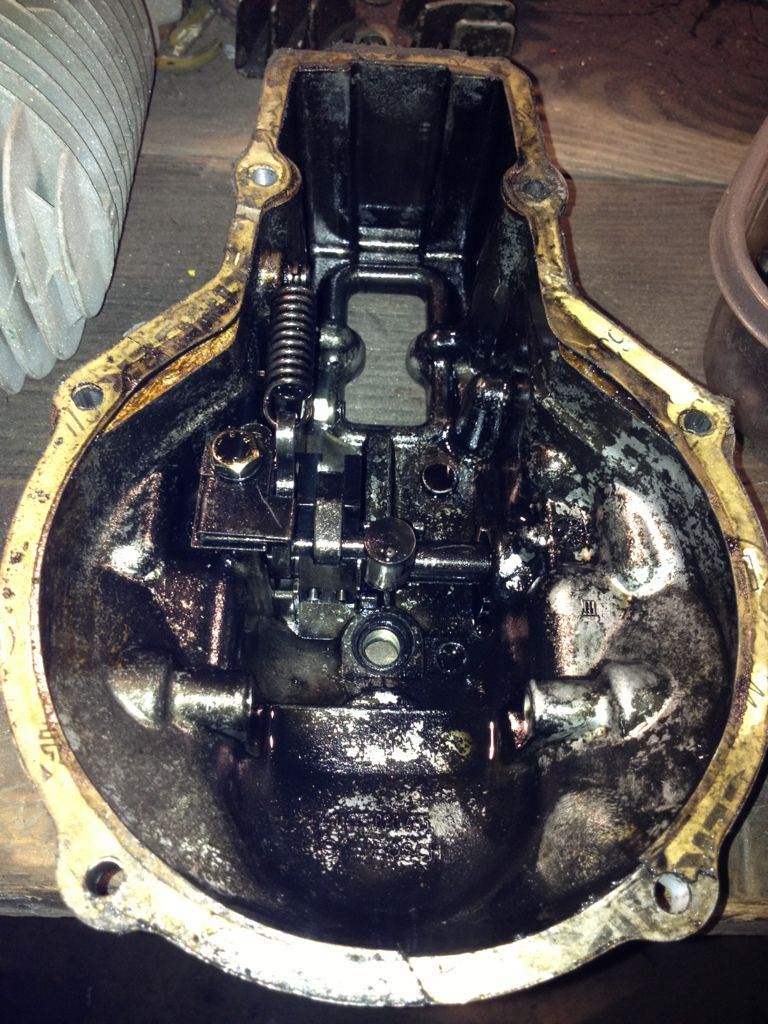

I didn't just break out a welder and a grinder, I took the time to know what I was accomplishing.

m880cummins wrote:Attitude comes from the way you present yourself here on the forum (which neither of us can change). I'm not copping, I'm fully aware of my modifications jepordizing the outcome of a typical fender bender in a court of law etc. and have known this growing up around my family and friends who modify and customize vehicles all the time.

Your attitude comes off as being a gung-ho kid with inexperience, which if you don't stop and take a reasoned look at what you're trying to do here, will bite you in the ass later.

Put your emotions aside and look at it from the standpoint of how much unnecessary work you are doing.

m880cummins wrote:Wonder why you aren't showing up on FABO anymore?

Charlie

I go there sometimes, wonderful site, don't log in much, since I no longer have Mopars to ask questions about.

Sure miss my old 69 340 4 speed Swinger.

Mark.