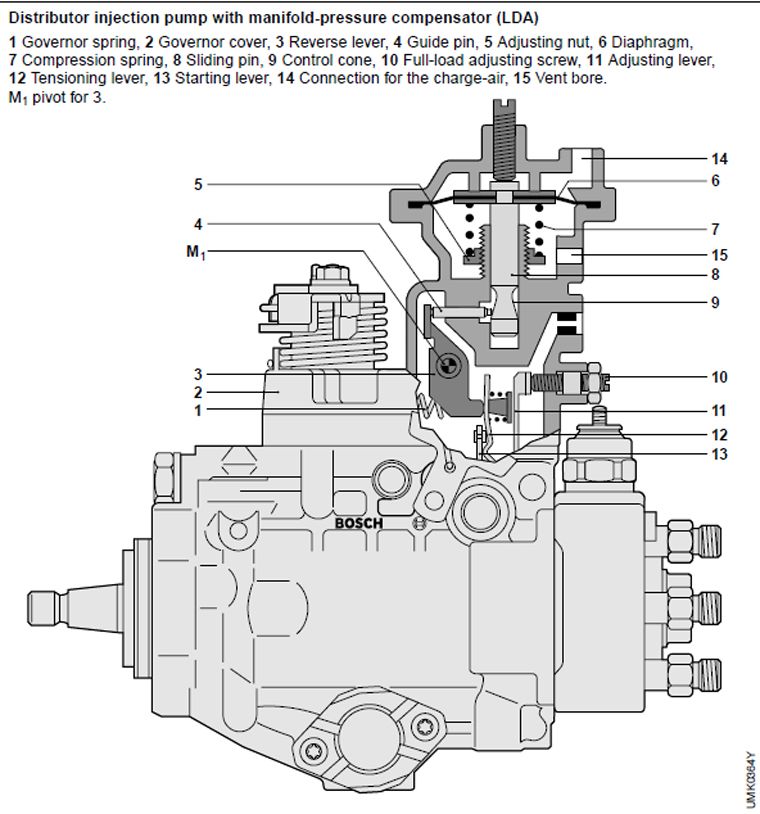

You know deep-cut fuel-pins can perhaps over-extend the needle thingy resulting in fuel leaking . . ..

So, on my mess, I've modified the profile of that fulcrum-lever's foot (Reverse Lever in image above), (Remember when folks used to grind that foot completely off?

From this . . .

To this . . . .

See the difference?

The idea is that one can have a longer range of motion imparted to the Tension Lever (again, see above image) by the change in the profile of the Reversing Lever's foot. I think it equates to a change in the Ratio in movement there. It's small, but it's there.

The goal being to impart a greater range of motion to the Tension Lever, without such a radical profile of the Control Cone. Should aid in keeping the Guide Pin's range of motion within that of the associated sealing ring.

I'll get pics of the modified article shortly.

Thoughts?