'90 W250--'89/91/92 Ramcharger

Moderators: Greenleaf, KTA, BC847, Richie O

Re: '90 W250

Hopefully Saturday right after work, then I'll have a gun loaded and ready to spray primer on it as soon as it's done and cleaned. I'd like to have it painted done, and out of there by Monday. It keeps the flares from the bosses down.

1990 W250 4x4

Rattles, growls, whistles, and whines.

Rattles, growls, whistles, and whines.

-

Tacoclaw - 14mm rotor

- Posts: 4120

- Joined: Wed Mar 11, 2009 7:50 am

- Location: Cheshire, OH

Re: '90 W250

Alrighty, boys, once again before I have to risk asking on CompD.

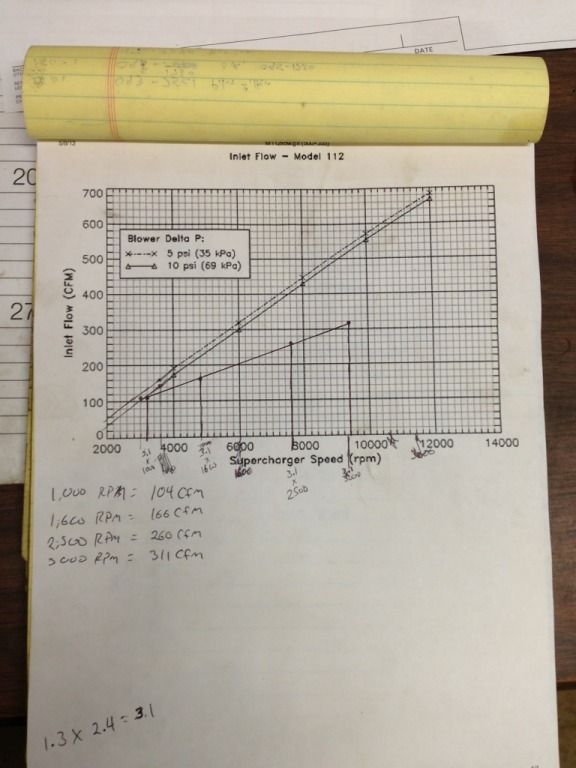

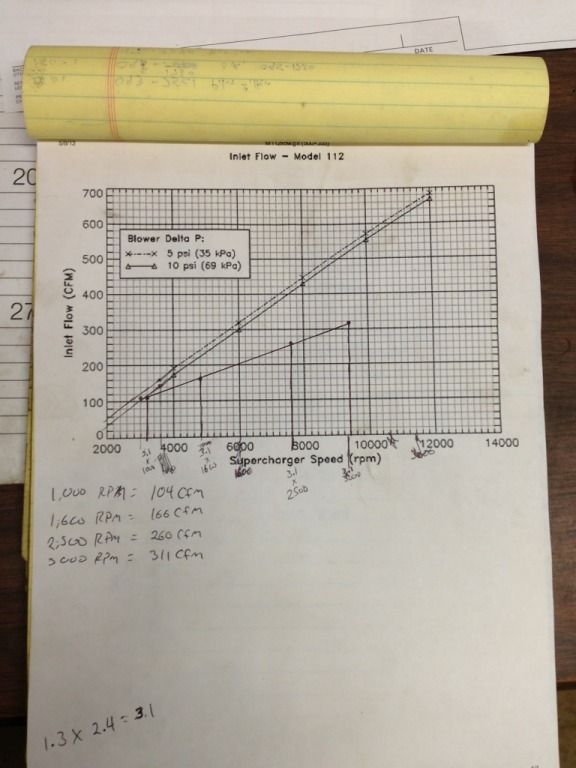

I'm working with the RPMxcid/3456=CFM equation. As you can see in this pic I scribbled all over, you pretty much just drop a zero off the RPM you're at and that's what a 5.9 will want CFM-wise. My question is this, is that what the engine is guaranteed to be pulling at those RPMs? Is that the bare minimum required or is that a best-case scenario number guaranteed to burn all the fuel needed to maintain that RPM?

I'm dealing with this chart, the lower, less steep line is the CFM requirements of a 5.9 at those RPMs. The steeper lines are the blower input(I assume that's also the output since it's a positive displacement pump) CFMs. At 1000rpm, where I need a little pep, it looks like the blower is just putting out the 100 CFM the engine needs. This is with my best case, and expensive, 3.1 drive ratio I've been able to track down. Of course once RPMs ramp up the blower far outpaces the CFM needs of the engine, but that'll drop as the boost comes up.

Thoughts on if this thing, numerically anyways, is going to make any difference at the 1k rpm range?

Like I said, this is all tied into just what that equation is calculating exactly. If my truck would only pull 104CFM at 1k if it's inlet was exactly as big around as the piston, then this isn't an issue.

As an edit, this is all assumed N/A. I figure my turbo starts lighting around 18-2200. I have no real idea since I have no tach, but earballing it that's what I'm going to say. The blower output doesn't amount to much once above that RPM because the turbo starts putting out more CFM than it can pull by that time.

I'm working with the RPMxcid/3456=CFM equation. As you can see in this pic I scribbled all over, you pretty much just drop a zero off the RPM you're at and that's what a 5.9 will want CFM-wise. My question is this, is that what the engine is guaranteed to be pulling at those RPMs? Is that the bare minimum required or is that a best-case scenario number guaranteed to burn all the fuel needed to maintain that RPM?

I'm dealing with this chart, the lower, less steep line is the CFM requirements of a 5.9 at those RPMs. The steeper lines are the blower input(I assume that's also the output since it's a positive displacement pump) CFMs. At 1000rpm, where I need a little pep, it looks like the blower is just putting out the 100 CFM the engine needs. This is with my best case, and expensive, 3.1 drive ratio I've been able to track down. Of course once RPMs ramp up the blower far outpaces the CFM needs of the engine, but that'll drop as the boost comes up.

Thoughts on if this thing, numerically anyways, is going to make any difference at the 1k rpm range?

Like I said, this is all tied into just what that equation is calculating exactly. If my truck would only pull 104CFM at 1k if it's inlet was exactly as big around as the piston, then this isn't an issue.

As an edit, this is all assumed N/A. I figure my turbo starts lighting around 18-2200. I have no real idea since I have no tach, but earballing it that's what I'm going to say. The blower output doesn't amount to much once above that RPM because the turbo starts putting out more CFM than it can pull by that time.

1990 W250 4x4

Rattles, growls, whistles, and whines.

Rattles, growls, whistles, and whines.

-

Tacoclaw - 14mm rotor

- Posts: 4120

- Joined: Wed Mar 11, 2009 7:50 am

- Location: Cheshire, OH